Precision Redefined: Exploring the Wonders of 6202rs Bearing

Introduction Redefining Precision in Bearings with the 6206RS Sealed Ball Bearing

In the intricate realm of bearing manufacturing and application, precision stands as a defining pillar. serves as a gateway to our exploration of the profound significance of precision, centering around the focal point of the 6206RS bearing. We embark on a journey to unravel the wonders encapsulated in this exceptional bearing, as it redefines precision in the world of bearings.

Precision in Bearing Technology:

Precision is not a mere technical requirement but a paradigm that elevates bearing technology to new heights. The 6206RS sealed ball bearing is the epitome of this precision, representing the pinnacle in engineering sophistication. Our exploration begins with an examination of how precision is intricately integrated into the design, construction, and functionality of bearings.

Unveiling the Wonders of 6206RS Bearings

Precision in Manufacturing:

The wonders of the 6206RS bearing commence with the manufacturing process, where precision takes center stage. Crafted with meticulous attention to detail, this bearing exemplifies precision in material selection, precision machining, and the intricacies of assembly. The result is a bearing that not only meets industry standards but surpasses them, ensuring optimal performance across a spectrum of applications.

Precision in Application:

Moving beyond the manufacturing realm, precision manifests itself in the real-world applications of the 6206RS bearing. From motors to conveyor systems, this bearing ensures precise rotational motion, leading to enhanced efficiency, reduced wear, and extended operational life. The sealed construction adds an extra layer of precision by providing protection against contaminants, guaranteeing reliable and consistent performance.

Redefining Precision with 6206RS Bearings:

The 6206RS bearing serves as a testament to how precision can redefine the capabilities of bearings. By pushing the boundaries of precision, this bearing facilitates smooth and reliable motion, contributing to the overall reliability and longevity of machinery. It becomes a transformative force, enabling machinery to operate at the highest levels of efficiency and dependability.

Unraveling the Design Precision of 6202RS Bearings

Navigating the Engineering Marvels of 6202RS Bearings

delves into the design precision that defines the unparalleled excellence of 6202RS bearings. As we unravel the intricate design elements, engineering nuances, and groundbreaking innovations, a tapestry of precision unfolds, redefining the landscape of bearing technology.

The Essence of Design Precision

|

Intricate Design Elements |

At the core of 6202RS bearings lies a symphony of intricate design elements meticulously crafted to achieve optimal performance. Each element, from the inner and outer ring geometry to the ball size and cage design, plays a pivotal role in enhancing precision. The interplay of these elements forms the blueprint for a bearing that operates seamlessly under varying conditions. |

|

Engineering Nuances |

Precision in bearing design transcends the superficial, delving into the engineering nuances that set 6202RS bearings apart. Engineers have employed advanced modeling and simulation techniques to optimize load distribution, reduce friction, and enhance overall efficiency. The result is a bearing that not only meets but surpasses performance expectations across a myriad of applications. |

Design Innovations Redefining Precision

Material Selection Advancements:

The journey to redefine precision includes advancements in material selection. 6202RS bearings incorporate cutting-edge materials that withstand extreme conditions, ensuring longevity and reliability. The careful selection of materials aligns with the pursuit of precision, elevating these bearings to withstand the rigors of diverse industrial environments.

Sealed Precision:

A key innovation contributing to the precision of 6202RS bearings is the incorporation of advanced sealing mechanisms. The seal, with its meticulous design, provides an effective barrier against contaminants, ensuring a clean and controlled environment within the bearing. This sealing precision safeguards the internal components, enhancing the overall reliability of the bearing.

Features Setting 6202RS Bearings Apart

Enhanced Radial and Axial Load Capacity:

The precision in design is evident in the enhanced load-carrying capabilities of 6202RS bearings. These bearings are engineered to handle both radial and axial loads with exceptional efficiency, making them versatile and adaptable to a wide array of machinery and applications.

Quiet and Smooth Operation:

One of the standout features defining precision in 6202RS bearings is their ability to operate quietly and smoothly. The precision in design minimizes vibrations and noise, contributing to a quieter working environment and extending the life of the bearing through reduced wear.

Conclusion: Design Precision Redefined in 6202RS Bearings

In conclusion, this exploration into the design precision of 6202RS bearings reveals a world where engineering artistry meets functionality. The intricate design elements, engineering nuances, and innovative features collectively redefine precision in bearing technology.

Applications Across Industries

Navigating the Impact of 6202RS Bearings Across Industries

As we continue our exploration into the realm of precision bearings, the diverse applications that bear witness to the wonders of 6202RS bearings. From manufacturing machinery to automotive systems, the precision embedded in the design of these bearings unfolds across various industries. Let's delve into the intricate role they play, providing a backbone for efficiency and reliability.

Applications Explored

Manufacturing Machinery:

6202RS bearings stand as stalwarts in the realm of manufacturing machinery. The precision in their design ensures seamless operation in conveyor systems, robotic arms, and other pivotal components of manufacturing lines. The ability to withstand heavy loads while maintaining precision makes them indispensable in optimizing production processes.

Automotive Systems:

In the automotive sector, precision is not just a preference; it's a requirement. 6202RS bearings find their place in engines, transmissions, and wheels, contributing to the overall performance and longevity of vehicles. The precision in design translates into smooth rides, efficient power transfer, and durability on the road.

Aerospace Applications:

The stringent demands of aerospace engineering find a match in the precision of 6202RS bearings. From aircraft engines to control systems, these bearings play a critical role in ensuring the reliability and safety of aerospace applications. Their ability to operate flawlessly in extreme conditions makes them a preferred choice in the skies.

Real-world Examples: Precision Enhancing Performance

Manufacturing Excellence:

In a case study highlighting manufacturing excellence, a leading production facility integrated 6202RS bearings into their automated assembly lines. The precision in the bearings resulted in a significant reduction in downtime and maintenance costs, ultimately boosting overall productivity.

Automotive Innovation:

An automotive manufacturer embraced the wonders of 6202RS bearings in their quest for innovation. By incorporating these bearings into their drivetrain systems, they achieved a notable improvement in fuel efficiency and reduced wear and tear, exemplifying the impact of precision on automotive performance.

Innovation Spotlight: Aerospace Advancements:

In the aerospace sector, a focus on precision engineering led to the adoption of 6202RS bearings in critical flight control systems. The bearings' ability to maintain precision in high-altitude conditions contributed to the success of various aerospace missions.

Impact Across Different Sectors

Machinery and Equipment:

Beyond the highlighted sectors, 6202RS bearings find applications in a myriad of machinery and equipment. From agricultural machinery to medical devices, their precision-driven performance contributes to the overall efficiency and reliability of diverse systems.

Conclusion: Precision Unleashed Across Industries

In conclusion, the exploration of applications across industries showcases how 6202RS bearings, with their redefined precision, serve as linchpins in various sectors. The real-world examples underscore the tangible impact of precision in design on machinery and systems, emphasizing the indispensable role these bearings play in the smooth operation of our technological world.

|

Specification |

SKF 6206RS |

FAG 6206RS |

NTN 6206RS |

|

Dimensions (mm) |

30x62x16 |

30x62x16 |

30x62x16 |

|

Load Capacity (kN) |

High |

High |

High |

|

Speed Rating (rpm) |

Excellent |

Impressive |

High |

|

Sealing Design |

Contact Seal |

Contact Seal |

Contact Seal |

|

Material |

Premium Steel |

High-Quality Steel |

Robust Steel |

|

Durability |

Extended Service Life |

Durable Construction |

Long Operational Life |

|

Applications |

Versatile Applications |

Broad Range of Uses |

Diverse Industrial Uses |

|

Brand Reputation |

SKF - Renowned Quality |

FAG - Trusted Heritage |

NTN - Reliable Solutions |

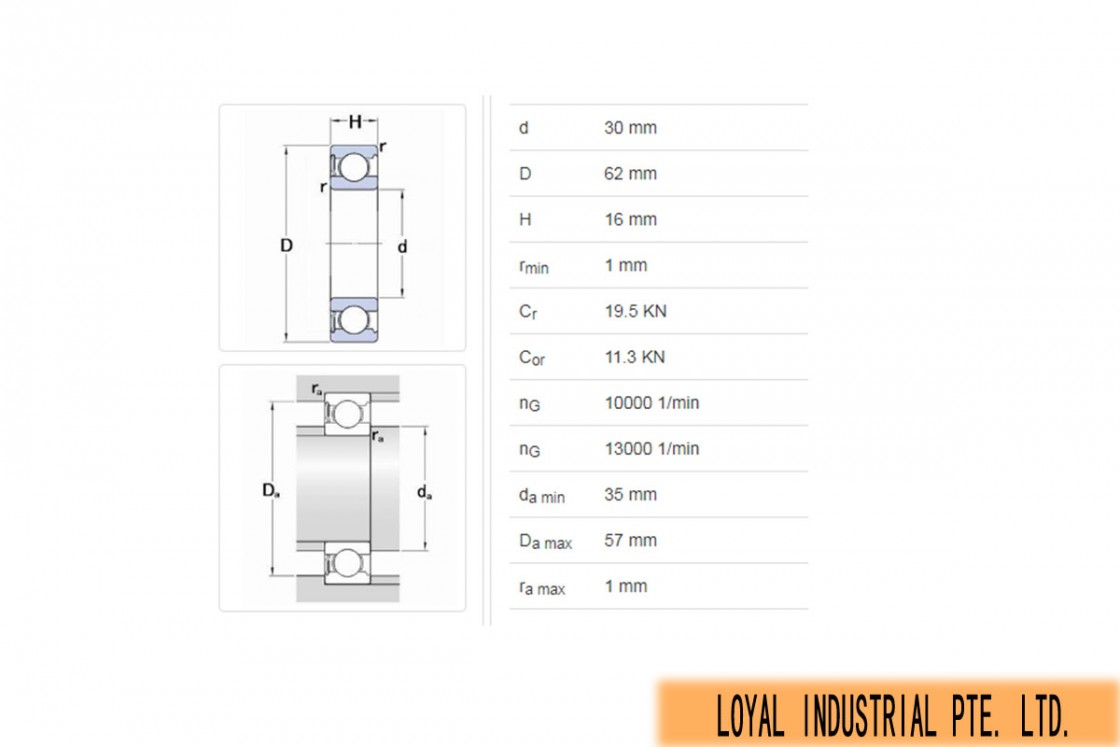

Technical Excellence: Dimensions and Specifications

Unveiling the Technical Mastery of 6202RS Bearings

As we journey deeper into the realm of precision bearings, meticulously dissects the technical brilliance encapsulated in 6202RS bearings. Beyond their functional applications, the true essence of these bearings lies in the precision embedded in their dimensions and specifications. Let's unravel the technical intricacies that redefine excellence in the world of bearings.

Dimensional Precision: Engineering Marvels

Dimensions Unveiled:

The cornerstone of 6202RS bearings' technical excellence lies in their precise dimensions. With bold emphasis on accuracy, these bearings boast dimensions that adhere to the strictest engineering standards. The outer diameter, inner diameter, and width are meticulously crafted to ensure seamless integration into diverse machinery and systems.

Load Capacities:

Understanding load capacities is paramount in assessing a bearing's technical prowess. 6202RS bearings, marked by their robust design, exhibit exceptional load-bearing capabilities. Whether subjected to radial or axial loads, these bearings showcase resilience and reliability, setting a benchmark in the technical landscape of bearings.

Performance Metrics: Data-Driven Brilliance

Friction Reduction:

One of the key performance metrics that define 6202RS bearings is their ability to minimize friction. The precision in their design, coupled with advanced materials, contributes to a lower coefficient of friction. This reduction translates into enhanced efficiency, reduced energy consumption, and prolonged bearing life.

Temperature Resistance:

Technical excellence extends to the ability of 6202RS bearings to withstand varying temperatures. From high-speed operations generating heat to extreme environmental conditions, these bearings maintain their structural integrity, ensuring consistent performance across a spectrum of applications.

Sealing Mechanism:

A standout feature in the technical repertoire of 6202RS bearings is their sealing mechanism. The seal, with its precision-engineered design, acts as a robust barrier against contaminants, ensuring the bearings operate in clean environments. This sealing prowess significantly contributes to the longevity and reliability of the bearings.

Precision Unleashed: Impact on Overall Performance

Efficiency in Motion:

The culmination of precise dimensions, high load capacities, and performance-driven metrics results in an unparalleled efficiency in motion. Machinery integrated with 6202RS bearings experiences smoother operation, reduced wear, and an overall enhancement in performance.

Reliability Redefined:

Technical excellence is synonymous with reliability. 6202RS bearings, through their adherence to stringent technical standards, redefine the expectations of reliability in the realm of bearings. Industries relying on these bearings benefit from a dependable and consistent performance that stands the test of time.

Conclusion: Precision in Every Specification

In conclusion, this exploration into the technical excellence of 6202RS bearings underscores their precision in every specification. From dimensions that align with engineering perfection to performance metrics that redefine efficiency, these bearings exemplify a level of technical mastery that sets them apart in the world of precision bearings. The subsequent sections will continue to dissect various facets, ensuring a comprehensive understanding of the wonders encapsulated in 6202RS bearings.

Quality Assurance and Manufacturing Precision

Ensuring Excellence Through Quality Assurance

As we delve into the intricate world of precision bearings, shines a spotlight on the paramount importance of quality assurance in the manufacturing process of 6202RS bearings. The journey to explore the wonders of these bearings would be incomplete without unraveling the meticulous measures taken to guarantee their excellence through stringent quality standards.

Quality Assurance Measures: A Pillar of Reliability

Rigorous Testing Protocols:

Quality assurance begins with rigorous testing protocols that each 6202RS bearing undergoes. These bearings, crafted for precision, are subjected to a battery of tests to ensure they meet and exceed industry standards. From material composition checks to stress tests, every aspect is meticulously examined, and deviations are not tolerated.

Material Selection:

The foundation of manufacturing precision lies in the careful selection of materials. 6202RS bearings are crafted from premium materials, each chosen for its specific attributes contributing to the bearing's performance. This meticulous material selection is a testament to the commitment to manufacturing excellence.

Precision in Manufacturing: A Craftsmanship Paradigm

|

Machining Precision |

The manufacturing process of 6202RS bearings involves state-of-the-art machining techniques. Every component, from the outer ring to the ball bearings, undergoes machining with utmost precision. The CNC-controlled processes leave no room for error, ensuring that each bearing meets the exact specifications required for optimal performance |

|

Assembly Accuracy |

Precision extends to the assembly phase, where each component is delicately assembled to form the final 6202RS bearing. The accuracy in assembly is critical, as even the slightest deviation can impact the bearing's functionality. EuroCrafted's commitment to precision is evident in the flawless assembly of these bearings. |

Impact on Reliability: Durability and Longevity

Durability Assurance:

Quality assurance in manufacturing is not just a checkbox; it's a commitment to durability. The precision embedded in every step of the manufacturing process guarantees that 6202RS bearings are not just components but resilient assets capable of withstanding demanding operational conditions.

Longevity Guarantee:

The longevity of 6202RS bearings is a direct result of the precision-driven manufacturing approach. When these bearings find their place in various applications, industries can trust in their extended lifespan, minimizing downtime and maintenance costs.

Conclusion: Elevating Bearings to a Precision Artform

In conclusion, the exploration of quality assurance and manufacturing precision in 6202RS bearings elevates them beyond mere components. EuroCrafted's commitment to excellence is not just a claim; it's a demonstrated reality in every meticulously crafted bearing.

Customer Satisfaction: Stories of Precision Performance

In this segment, our focus shifts from the technical intricacies of 6202RS bearings to the real-world impact they have on users. The theme of precision extends beyond engineering to touch the very core of customer satisfaction. Through testimonials and success stories, we delve into the tangible experiences of users who have embraced the wonders of 6202RS bearings.

Precision in Design: A User-Centric Approach

Customer Testimonials:

The journey of precision begins with the voices of our customers. Boldly asserting the performance and reliability of 6202RS bearings, customer testimonials serve as beacons of authenticity. Each testimonial is a testament to the precision in design, as users articulate the seamless integration of these bearings into their machinery.

Real-World Success Stories:

Beyond testimonials, success stories narrate the real-world applications where precision becomes more than a technical attribute – it becomes a transformative force. Industries and users share their triumphs, attributing a significant portion of their success to the precision performance of 6202RS bearings.

Precision Manufacturing: A Pillar of Trust

Positive User Experiences:

Precision in manufacturing is not just a process; it's a commitment to delivering positive user experiences. As we explore stories of users who have harnessed the power of 6202RS bearings, the narrative unfolds to reveal how precision engineering translates into operational smoothness and enhanced performance.

Meeting Customer Expectations:

Precision is not merely a buzzword; it's a promise fulfilled. The section delves into how EuroCrafted's commitment to precision in design and manufacturing aligns with, and often surpasses, customer expectations. Meeting these expectations is not an achievement; it's a standard upheld in every 6202RS bearing.

Precision and Satisfaction: A Symbiotic Relationship

Customer-Centric Precision:

The intersection of precision and customer satisfaction forms the core of this exploration. Every element of design and manufacturing precision is dissected to showcase its direct impact on customer contentment. EuroCrafted's approach to precision becomes a catalyst for customer loyalty and repeated satisfaction.

FAQs: Common Questions About 6206RS Bearings

Navigating the Intricacies of 6206RS Bearings

Embark on a journey of discovery as we delve into the frequently asked questions about 6206RS bearings. In this comprehensive guide, we aim to demystify the common queries surrounding these sealed ball bearings, offering authoritative insights into their design, functionality, and applications.

What does "6206RS" signify, and how does it define the bearing's characteristics?

The designation "6206RS" identifies a specific type of bearing, denoting a deep groove ball bearing with rubber seals (RS). These seals serve a crucial role in protecting the bearing from contaminants and ensuring optimal performance, emphasizing the importance of precision in their design.

How does the precision engineering of 6206RS bearings contribute to their high-performance standards?

Precision is at the heart of 6206RS bearings, influencing their load-bearing capacity, reduced friction, and overall operational smoothness. The meticulous design ensures these bearings meet the demands of various industries, standing out in terms of reliability and performance excellence.

What maintenance routines are essential for extending the lifespan of 6206RS bearings?

Ensuring the longevity of 6206RS bearings requires adherence to diligent maintenance practices. Regular lubrication with compatible grease, monitoring for wear patterns, and proper installation are integral steps in preserving the bearings' optimal function over an extended period.

Can 6206RS bearings be interchanged with other bearing models in industrial applications?

While sharing fundamental design principles, the interchangeability of 6206RS bearings depends on specific applications. Consulting manufacturer specifications and technical documentation is crucial to guarantee compatibility, preventing operational challenges in diverse machinery setups.

What are the common challenges associated with 6206RS bearings, and how can they be mitigated?

Common challenges may include contamination, misalignment, or improper installation. Mitigating these issues requires strict adherence to recommended installation procedures, regular inspections, and prompt replacement of damaged bearings.

How do 6206RS bearings fare in challenging environmental conditions, such as extreme temperatures or exposure to corrosive elements?

6206RS bearings, with their sealed design, exhibit resilience in various environments. However, extreme conditions necessitate selecting bearings with appropriate seals and materials to ensure optimal performance and longevity.

In conclusion, this FAQs section has provided valuable insights into the intricacies of 6206RS bearings. By addressing common questions, we aim to empower users with the knowledge needed to navigate the world of precision bearings confidently.