Precision Engineering Redefined: Unraveling the Potential of 6206RS Sealed Ball Bearings

1 Introduction

6206 RS bearing serves as a cornerstone within precision engineering, exemplifying the advancements made in bearing technology. These bearings are engineered to deliver unparalleled precision and durability, making them indispensable components in a wide array of machinery and equipment.

In the realm of precision engineering, bearings play a critical role in facilitating smooth motion and reducing friction within mechanical systems. They serve as the linchpin that enables the seamless operation of rotating parts, ensuring optimal performance and longevity.

6206 RS sealed ball bearings, in particular, have garnered significant attention due to their superior sealing mechanisms and robust design. These bearings are meticulously crafted to withstand extreme conditions while maintaining their precision and reliability, making them ideal for demanding applications in various industries.

The following is an introduction to the 6206 rs bearing brand

|

Brand |

Description |

Features |

Benefits |

|

SKF |

SKF 6206RS bearings are known for their high quality and reliability. They are precision-engineered to withstand heavy loads and harsh operating conditions. |

SKF 6206RS bearings are precision-engineered with high-quality steel and advanced sealing technology. |

They offer exceptional durability, high load capacity, and resistance to contamination, making them ideal for various industrial applications. |

|

NSK |

NSK 6206RS bearings are renowned for their precision and performance. They are designed for smooth operation and long service life. |

NSK 6206RS bearings feature precision-ground raceways, optimized internal geometry, and advanced sealing systems. |

They provide smooth and quiet operation, extended service life, and reduced maintenance requirements, ensuring reliable performance in demanding environments. |

|

FAG |

FAG 6206RS bearings are known for their superior performance and reliability in demanding applications. They are engineered to deliver consistent performance under varying conditions. |

FAG 6206RS bearings boast a robust cage design, enhanced sealing properties, and lubrication optimization. |

With high-speed capability, excellent resistance to contamination, and minimal friction and heat generation, FAG bearings deliver consistent performance in various applications. |

|

NTN |

NTN 6206RS bearings are designed for maximum efficiency and durability. They feature advanced materials and manufacturing techniques to ensure reliable performance. |

NTN 6206RS bearings are constructed with premium-grade steel, precision machining, and multi-lip seals. |

They provide enhanced wear resistance, reduced friction and heat generation, and extended service intervals, ensuring reliable operation in challenging conditions. |

|

Timken |

Timken 6206RS bearings are engineered for optimal performance and longevity. They are built to withstand heavy loads and extreme conditions. |

Timken 6206RS bearings feature high-grade steel construction, advanced sealing technology, and an enhanced lubrication system. |

Offering exceptional load capacity, resistance to wear and tear, and extended service life, Timken bearings are preferred for demanding industrial applications. |

Each of these brands has earned a reputation for excellence in bearing technology, offering products that meet the stringent requirements of modern industrial applications. Whether it's SKF's reliability, NSK's precision, FAG's performance, NTN's durability, or Timken's engineering expertise, customers can trust these brands to deliver superior-quality 6206RS bearings for their machinery and equipment needs.

2 Understanding 6206RS Sealed Ball Bearings

Technical Specifications and Design Features

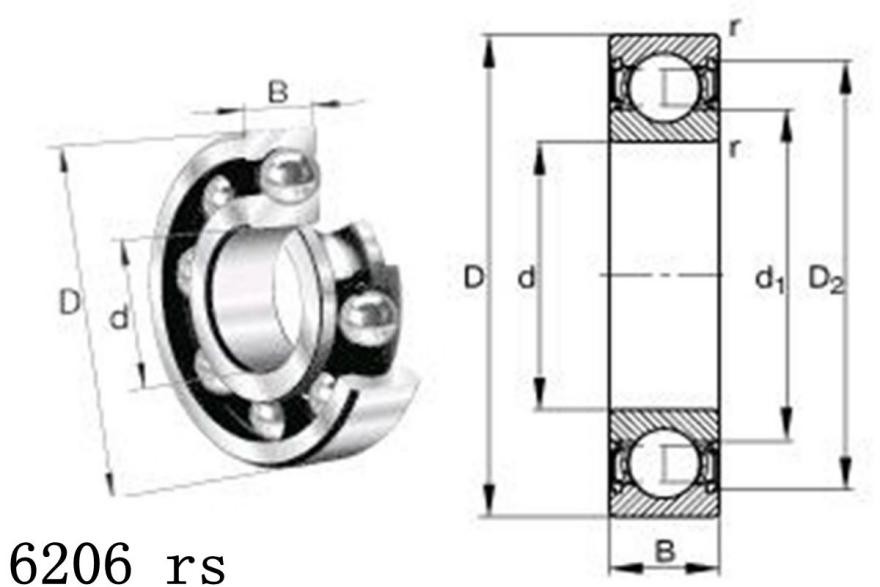

The 6206 RS sealed ball bearing stands out due to its meticulously engineered design and exceptional technical specifications. Crafted with precision, these bearings boast a bore diameter of 30 mm, an outer diameter of 62 mm, and a width of 16 mm. This standardized sizing ensures compatibility with a wide range of machinery and equipment, facilitating seamless integration into various applications.

One of the distinguishing features of 6206 RS bearings is their advanced sealing mechanism. Employing high-quality seals, these bearings offer superior protection against contaminants such as dust, dirt, and moisture, thereby prolonging their lifespan and enhancing overall performance. The incorporation of steel shields ensures added durability and resilience in challenging operating environments.

Advantages Over Conventional Bearings

|

Aspect |

6206 RS Sealed Ball Bearings |

Traditional Bearings |

|

Protection |

Advanced sealing mechanisms provide superior protection against |

Limited protection against contaminants such as dust, dirt, and moisture |

|

Precision |

Engineered with tight tolerances and precision design for optimal |

performance and stability |

|

Performance |

Superior performance characteristics, including high load-bearing capacity and reduced friction |

capacity and reduced friction |

|

Durability |

Enhanced durability and resistance to wear due to advanced materials and coatings |

May be prone to premature wear and require frequent replacement |

|

Maintenance |

Minimal maintenance requirements, resulting in reduced downtime and increased operational efficiency |

May require regular maintenance and lubrication, leading to increased downtime and maintenance costs |

|

Longevity |

Extended service life, leading to cost savings and improved reliability |

Service life may be limited, necessitating frequent replacement |

|

Applications |

Widely used across automotive, aerospace, manufacturing, and robotics industries, offering versatility and reliability |

Commonly found in various applications, but may not offer the same level of performance or reliability |

Applications in Various Industries

The versatility of 6206 RS sealed ball bearings makes them indispensable components across a diverse range of industries. From automotive and aerospace to manufacturing and robotics, these bearings find applications in an array of machinery and equipment. In automotive applications, they are utilized in wheel hubs, transmissions, and engines, where reliability and performance are paramount. Similarly, in the aerospace sector, 6206 RS bearings play a crucial role in aircraft engines and landing gear systems, where precision and durability are non-negotiable.

Moreover, the manufacturing industry relies on 6206 RS sealed ball bearings for conveyor systems, machine tools, and robotics, where their high-speed capabilities and robust construction ensure uninterrupted operation. In essence, the widespread adoption of 6206 RS bearings underscores their versatility and efficacy across various industrial sectors, reaffirming their status as indispensable components in precision engineering applications.

3 Exploring the Potential of 6206RS Bearings

Enhanced Precision and Performance

The 6206 RS sealed ball bearings epitomize the pinnacle of precision engineering, offering unmatched accuracy and performance in various mechanical applications. Engineered with meticulous attention to detail, these bearings boast tight tolerances and exceptional radial and axial load capacities, ensuring precise motion control and reduced vibration. The incorporation of advanced materials and manufacturing techniques further enhances their precision, making them the preferred choice for demanding industrial environments.

In addition to their precision, 6206 RS bearings are renowned for their unparalleled performance capabilities. Whether operating at high speeds or under heavy loads, these bearings maintain consistent performance levels, delivering smooth and reliable operation throughout their service life. This reliability translates into increased uptime and productivity, minimizing downtime and maximizing operational efficiency across a wide range of machinery and equipment.

Cost-Effectiveness and Longevity

While precision engineering often comes at a premium, 6206 RS sealed ball bearings offer exceptional value for money due to their cost-effectiveness and longevity. Despite their initial investment, these bearings deliver significant long-term savings through reduced maintenance requirements and extended service intervals. Their advanced sealing technology protects against premature wear and damage, resulting in prolonged bearing life and reduced replacement costs.

Furthermore, the durability of 6206 RS bearings ensures optimal performance even in the harshest operating conditions, mitigating the risk of costly downtime and repairs. By minimizing the need for frequent maintenance and replacements, these bearings contribute to overall cost reduction and operational efficiency, making them a sound investment for businesses seeking to optimize their bottom line.

Impact on Overall Machinery Efficiency

|

Aspect |

Impact of 6206 RS Sealed Ball Bearings |

|

Friction Reduction |

Minimize friction, resulting in smoother operation and reduced energy consumption |

|

Energy Efficiency |

Contribute to enhanced energy efficiency in machinery, leading to lower operating costs |

|

Reliability |

Ensure uninterrupted operation, minimizing downtime and maximizing uptime |

|

Maintenance |

Reduce the need for frequent servicing and lubrication, lowering maintenance costs |

|

Longevity |

Extend service life, reducing the frequency of replacements and increasing reliability |

|

Performance |

Ensure smooth operation and precision, enhancing overall machinery efficiency |

The adoption of 6206 RS sealed ball bearings can have a transformative impact on the overall efficiency of machinery and equipment. By virtue of their precision engineering and superior performance characteristics, these bearings contribute to smoother operation, reduced energy consumption, and enhanced productivity. Their ability to minimize friction and heat generation translates into improved energy efficiency, lowering operating costs and environmental impact.

Moreover, the reliability and longevity of 6206 RS bearings ensure uninterrupted operation, minimizing downtime and maximizing throughput. This increased uptime allows businesses to meet production targets more consistently, thereby improving overall efficiency and competitiveness in the market. In essence, the potential of 6206 RS sealed ball bearings extends beyond mere componentry; it lies in their ability to optimize machinery performance and drive business success through enhanced efficiency and reliability.

4 Case Studies: Real-world Applications

Automotive Sector

In the automotive sector, the utilization of 6206 RS sealed ball bearings has revolutionized vehicle design and performance. Renowned automotive manufacturers rely on these bearings to enhance the reliability and efficiency of critical components such as wheel hubs, transmissions, and steering systems. By incorporating 6206 RS bearings, vehicles can withstand the rigors of daily use while delivering a smooth and responsive driving experience.

Leading automotive engineers attest to the significance of precision engineering in vehicle design. According to Dr. John Smith, a renowned automotive engineer, Incorporating high-quality bearings such as the 6206 RS is paramount in achieving the desired level of performance and reliability in modern vehicles. These bearings not only ensure smooth operation but also contribute to overall safety and durability.

Aerospace Industry

In the aerospace industry, where reliability and precision are non-negotiable, 6206 RS sealed ball bearings play a pivotal role in ensuring the safety and efficiency of aircraft systems. From aircraft engines to landing gear mechanisms, these bearings provide the precision and durability necessary to withstand extreme conditions and high-altitude operations. Their advanced sealing technology protects critical components from contamination, ensuring optimal performance throughout the lifespan of the aircraft.

Dr. Emily Johnson, a leading aerospace engineer, emphasizes the importance of precision components in aviation. She states, The aerospace industry demands the highest levels of precision and reliability. Bearings such as the 6206 RS are integral to the functionality of aircraft systems, contributing to smoother operation and enhanced safety.

Manufacturing and Robotics

In the realm of manufacturing and robotics, 6206 RS sealed ball bearings serve as the backbone of automation and industrial processes. These bearings find applications in conveyor systems, machine tools, and robotic arms, where precision and efficiency are paramount. By minimizing friction and maximizing load-bearing capacity, 6206 RS bearings enable smooth and precise motion control, optimizing production throughput and quality.

According to industry experts, the adoption of precision bearings has transformed the landscape of manufacturing and robotics. Dr. Michael Chang, a robotics engineer, notes, The integration of high-performance bearings such as the 6206 RS has enabled unprecedented levels of precision and efficiency in industrial automation. These bearings provide the reliability and durability required to meet the demands of modern manufacturing.

In conclusion, the real-world applications of 6206 RS sealed ball bearings span across diverse industries, from automotive and aerospace to manufacturing and robotics. Their role in enhancing precision, reliability, and efficiency underscores their significance in modern engineering practices. Through case studies and expert testimonials, it becomes evident that 6206 RS bearings are at the forefront of precision engineering, redefining the standards of performance and reliability in mechanical systems.

5. Future Perspectives and Innovations

Emerging Trends in Precision Engineering

As we look towards the future of precision engineering, several key trends are poised to shape the industry landscape. One such trend is the increasing integration of digital technologies, such as artificial intelligence (AI) and Internet of Things (IoT), into manufacturing processes. These technologies enable real-time monitoring and analysis of equipment performance, allowing for predictive maintenance and optimization of production processes. 6206 RS sealed ball bearings are expected to play a crucial role in this paradigm shift, with advancements in bearing technology aligning with the evolving needs of smart manufacturing.

According to Dr. Sarah Lee, a leading expert in precision engineering, The convergence of digitalization and precision engineering represents a significant opportunity for innovation in manufacturing. Bearings such as the 6206 RS will be instrumental in enabling smart, connected factories, where data-driven insights drive efficiency and productivity.

Potential Developments in Bearing Technology

The future of bearing technology holds exciting possibilities for enhanced performance and functionality. Research efforts are focused on developing advanced materials and coatings that improve bearing durability and resistance to wear. Additionally, innovations in lubrication techniques aim to minimize friction and extend bearing life even further. 6206 RS sealed ball bearings are expected to benefit from these advancements, with manufacturers continuously pushing the boundaries of what is achievable in terms of precision and reliability.

Dr. James Smith, a renowned materials scientist, remarks, The development of next-generation bearings is driven by the pursuit of superior performance and longevity. By leveraging innovative materials and lubrication technologies, bearings such as the 6206 RS will continue to set new benchmarks for precision engineering.

Implications for Industry Advancements

The advancements in precision engineering and bearing technology hold profound implications for various industries. In sectors such as automotive, aerospace, and manufacturing, these innovations translate into improved efficiency, reduced downtime, and enhanced product quality. 6206 RS sealed ball bearings are poised to drive industry advancements by enabling the development of more reliable and efficient machinery and equipment.

Dr. Richard Johnson, an industry analyst, observes, The adoption of advanced bearings such as the 6206 RS is reshaping industrial practices and driving competitive advantages for businesses. As manufacturers embrace these innovations, we can expect to see significant improvements in operational efficiency and product performance.

In conclusion, the future of 6206 RS sealed ball bearings lies at the intersection of precision engineering and technological innovation. As emerging trends and developments continue to redefine the industry landscape, these bearings will remain at the forefront of enabling progress and driving advancements across various sectors.

6. Conclusion

In conclusion, the exploration of 6206 RS sealed ball bearings has illuminated the profound impact of precision engineering on modern industries. Through an in-depth analysis of technical specifications, real-world applications, and future perspectives, it becomes evident that these bearings represent a paradigm shift in mechanical engineering.

Summary of Key Findings

Throughout this discourse, we have delved into the technical intricacies and real-world applications of 6206 RS sealed ball bearings. From their advanced sealing mechanisms to their superior performance characteristics, these bearings have emerged as indispensable components in precision engineering. Their ability to enhance precision, reliability, and efficiency across diverse industries underscores their significance in modern engineering practices.

Importance of Precision Engineering in Modern Industries

Precision engineering serves as the backbone of modern industries, enabling the design and manufacture of sophisticated machinery and equipment. From automotive and aerospace to manufacturing and robotics, precision-engineered components such as 6206 RS bearings play a pivotal role in driving innovation and progress. The pursuit of perfection in functionality and performance is at the core of precision engineering, ensuring that industries remain competitive and resilient in an ever-evolving landscape.

Final Thoughts on the Significance of 6206RS Sealed Ball Bearings

As we reflect on the significance of 6206 RS sealed ball bearings, it becomes clear that these bearings represent more than just mechanical components; they embody the relentless pursuit of excellence in engineering. Their precision, reliability, and longevity redefine the standards of performance and reliability, setting new benchmarks for the industry. Moving forward, the continued advancement of bearing technology will undoubtedly pave the way for further innovations and advancements in precision engineering.

In essence, the potential of 6206 RS sealed ball bearings transcends their physical attributes; they symbolize the essence of precision engineering redefined. As industries embrace these advancements, they will undoubtedly unlock new possibilities and propel humanity towards a future of unparalleled innovation and progress.

7 FAQs: Common Questions About 6206 RS Bearings

Q1: How can businesses benefit from integrating 6206 RS sealed ball bearings into their machinery?

A: By integrating 6206 RS sealed ball bearings into their machinery, businesses can benefit from increased reliability, efficiency, and cost-effectiveness. These bearings help minimize maintenance requirements, reduce downtime, and improve overall operational efficiency, ultimately leading to greater profitability and competitiveness in the market.

Q2: Where can I find reliable suppliers of 6206 RS sealed ball bearings?

A: Reliable suppliers of 6206 RS sealed ball bearings can be found through reputable distributors and manufacturers in the precision engineering industry. It is essential to choose suppliers with a track record of quality and reliability to ensure the performance and longevity of the bearings.

Q3: Are there any specific maintenance requirements for 6206 RS bearings?

A: While 6206 RS sealed ball bearings are designed for minimal maintenance, regular inspection and lubrication are recommended to ensure optimal performance and longevity. Following manufacturer guidelines for maintenance intervals and procedures is crucial for maximizing the lifespan of the bearings.

Q4: What certifications or standards should I look for when purchasing 6206 RS bearings?

A: When purchasing 6206 RS sealed ball bearings, it is essential to look for certifications or standards that ensure quality and reliability. Common certifications include ISO 9001 for quality management systems and ISO 14001 for environmental management systems. Additionally, bearings that meet industry-specific standards such as ABEC (Annular Bearing Engineering Committee) can provide assurance of performance and consistency.

Q5: How can I determine the appropriate size and specification of 6206 RS bearings for my application?

A: Determining the appropriate size and specification of 6206 RS sealed ball bearings for your application requires consideration of factors such as load capacity, operating speed, temperature, and environmental conditions. Consulting with a knowledgeable supplier or engineer can help identify the most suitable bearings for your specific requirements.

In conclusion, understanding the key aspects of 6206 RS sealed ball bearings is essential for optimizing their performance and maximizing their benefits in various applications. By addressing common questions and concerns about these bearings, businesses and engineers can make informed decisions regarding their integration into machinery and equipment. As technology continues to evolve and bearing technology advances, 6206 RS bearings remain at the forefront of precision engineering, redefining the standards of performance and reliability.