Unlocking Efficiency: The Mechanics of Tapered Roller Bearings - TS (Tapered Single)

Introduction

Efficiency and reliability are paramount in the realm of mechanical systems, where precision engineering plays a crucial role in optimizing performance and minimizing downtime. At the heart of many industrial applications lie Tapered Roller Bearings - TS (Tapered Single), a type of bearing revered for its ability to withstand heavy radial and axial loads while facilitating smooth rotational motion. we delve into the mechanics of Tapered Roller Bearings - TS (Tapered Single) and explore their significance in unlocking efficiency across various industries.

Understanding Tapered Roller Bearings - TS (Tapered Single)

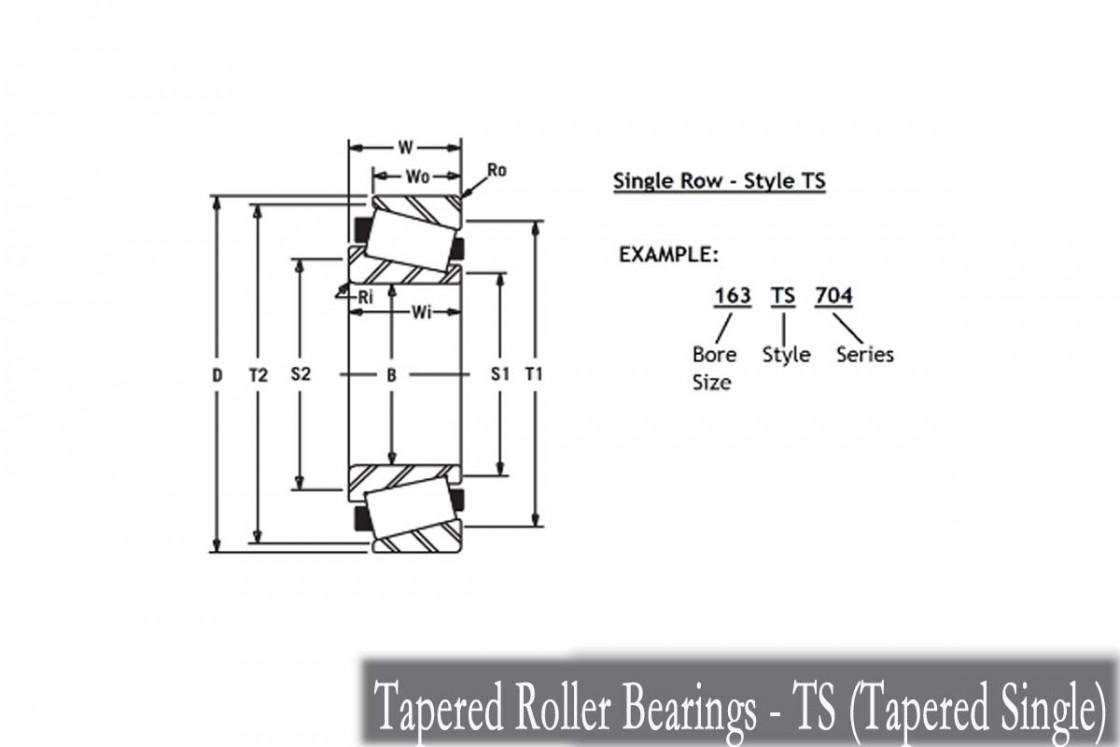

Tapered Roller Bearings - TS (Tapered Single) are engineered to handle both radial and axial loads by virtue of their unique tapered design. Comprising inner and outer rings with tapered raceways and tapered rollers, these bearings ensure optimal contact between the rollers and raceways, distributing loads evenly and minimizing stress concentrations. The tapered geometry allows for efficient transfer of forces, making TS bearings ideal for applications where axial displacement is required, such as automotive wheel hubs, gearboxes, and conveyor systems.

Advantages of Tapered Roller Bearings - TS (Tapered Single)

One of the key advantages of Tapered Roller Bearings - TS (Tapered Single) is their ability to accommodate both radial and axial loads simultaneously. This dual-load capacity makes TS bearings highly versatile and suitable for a wide range of applications across various industries. Additionally, the tapered design enables efficient distribution of loads, reducing the risk of premature wear and extending the service life of the bearing.

Applications of Tapered Roller Bearings - TS (Tapered Single)

Tapered Roller Bearings - TS (Tapered Single) find extensive use in industries where heavy-duty performance and reliability are paramount. From automotive drivetrains to heavy machinery and equipment, TS bearings play a critical role in ensuring smooth operation and minimizing downtime. Common applications include axle systems, transmission assemblies, agricultural machinery, and construction equipment.

Maintenance and Lubrication

Proper maintenance and lubrication are essential for maximizing the performance and longevity of Tapered Roller Bearings - TS (Tapered Single). Regular inspections, including checking for signs of wear, lubricant contamination, and proper preload, help detect potential issues early and prevent catastrophic failures. Additionally, selecting the appropriate lubricant and lubrication method is crucial for minimizing friction, reducing heat generation, and ensuring smooth bearing operation.

Conclusion

Tapered Roller Bearings - TS (Tapered Single) are integral components in efficient mechanical systems, offering unparalleled performance and reliability in handling radial and axial loads. By understanding the mechanics and applications of TS bearings, engineers and industry professionals can unlock efficiency and reliability in their machinery and equipment, driving productivity and minimizing downtime.

Understanding Tapered Roller Bearings - TS (Tapered Single)

Tapered Roller Bearings - TS (Tapered Single) represent a pinnacle of engineering in the field of bearings, renowned for their ability to handle radial and axial loads with exceptional efficiency and reliability.

|

Section |

Content |

|

Structure and Components |

At the core of Tapered Roller Bearings - TS (Tapered Single) lies a sophisticated arrangement of components meticulously designed to withstand heavy loads while ensuring smooth rotational motion. The inner and outer rings provide structural support and guidance for the tapered rollers, facilitating uniform load distribution. These tapered rollers, characterized by their conical shape, minimize stress concentrations and enable efficient transmission of forces. Additionally, cages are employed to retain and guide the rollers, enhancing overall stability and performance. |

|

Comparison with Other Bearings |

In comparison to conventional ball bearings and cylindrical roller bearings, Tapered Roller Bearings - TS (Tapered Single) stand out for their unique design tailored to handle both radial and axial loads simultaneously. While ball bearings excel in high-speed applications with light loads, TS bearings are preferred for applications requiring robust performance under heavy loads and variable operating conditions. Their tapered design allows for effective distribution of forces, making them suitable for applications such as automotive wheel hubs, gearboxes, and conveyor systems. |

|

Key Features and Characteristics |

Tapered Roller Bearings - TS (Tapered Single) boast a myriad of features and characteristics that make them indispensable in various engineering applications. Their ability to handle radial and axial loads simultaneously makes them highly versatile and suitable for a wide range of industrial machinery and equipment. Additionally, TS bearings exhibit high load capacity, excellent resistance to misalignment, and superior durability, ensuring reliable operation even in demanding environments. |

In conclusion, Tapered Roller Bearings - TS (Tapered Single) represent a cornerstone in efficient engineering design, offering unmatched performance and reliability in handling radial and axial loads. Their unique design and robust construction make them indispensable components in a multitude of industrial applications, driving efficiency and productivity across various industries.

Mechanics and Design Features of Tapered Roller Bearings - TS (Tapered Single)

Tapered Roller Bearings - TS (Tapered Single) stand as a pinnacle of engineering innovation, characterized by their unique mechanics and design features optimized for efficient load distribution and reduced friction.

Tapered Shape for Efficient Load Distribution

The tapered shape of the rollers and raceways is a fundamental aspect of Tapered Roller Bearings TS (Tapered Single), enabling them to handle radial and axial loads with exceptional efficiency. This design feature allows the rollers to transmit forces along the tapered surfaces, distributing the load evenly across the bearing's contact area. As a result, stress concentrations are minimized, and the bearing can withstand higher loads while maintaining optimal performance.

Cage Designs and Materials

The cage plays a crucial role in guiding and retaining the rollers within Tapered Roller Bearings - TS (Tapered Single), ensuring smooth operation and preventing roller skewing or misalignment. Various cage designs and materials are employed based on the specific application requirements. Common materials include steel, brass, and synthetic polymers, each offering distinct advantages in terms of durability, lubrication retention, and temperature resistance. The cage's design is carefully engineered to balance the need for robust roller guidance with minimal frictional losses.

Importance of Bearing Clearance, Preload Adjustment, and Lubrication

Proper bearing clearance, preload adjustment, and lubrication are essential factors in optimizing the performance of Tapered Roller Bearings - TS (Tapered Single). Adequate bearing clearance ensures smooth operation and accommodates thermal expansion, preventing excessive heat buildup and premature failure. Preload adjustment, achieved through controlled axial displacement of the bearing components, optimizes the load distribution and minimizes internal clearances, enhancing stiffness and reducing vibration. Additionally, selecting the appropriate lubricant and lubrication method is critical for minimizing friction, reducing wear, and preventing corrosion, ultimately extending the bearing's service life.

In essence, the mechanics and design features of Tapered Roller Bearings - TS (Tapered Single) are meticulously engineered to unlock efficiency and reliability in a wide range of industrial applications. From their tapered shape for efficient load distribution to the intricacies of cage design and lubrication, every aspect is optimized to deliver superior performance and durability, making them indispensable components in modern machinery and equipment.

Applications of Tapered Roller Bearings - TS (Tapered Single)

Tapered Roller Bearings - TS (Tapered Single) find widespread applications across various industries and machinery, owing to their unique design and exceptional performance characteristics.

Automotive Industry

In the automotive sector, Tapered Roller Bearings - TS (Tapered Single) play a crucial role in supporting wheel hubs, axles, and differentials. Their ability to handle both radial and axial loads makes them ideal for applications such as vehicle transmissions and steering systems. Additionally, TS bearings are employed in automotive gearboxes, where they ensure smooth power transmission and reliable operation even under high-speed and heavy-load conditions.

Aerospace Sector

In the aerospace industry, Tapered Roller Bearings - TS (Tapered Single) are utilized in critical components such as landing gear systems, wing flaps, and engine assemblies. These bearings offer exceptional load-carrying capacity and resistance to extreme temperatures, making them well-suited for the demanding operating conditions encountered in aircraft and spacecraft. The precise engineering and durability of TS bearings contribute to the safety and performance of aerospace equipment.

Industrial Equipment

Tapered Roller Bearings - TS (Tapered Single) are extensively used in various types of industrial machinery, including mining equipment, construction machinery, and agricultural machinery. They are employed in applications such as conveyor systems, gearboxes, and rotating shafts, where they provide reliable support and efficient power transmission. TS bearings are valued for their ability to withstand heavy loads, shock loads, and vibrations, enhancing the productivity and longevity of industrial equipment.

Performance Characteristics

Tapered Roller Bearings - TS (Tapered Single) exhibit a range of performance characteristics that make them suitable for diverse operating conditions.

High Load Capacity: TS bearings are designed to withstand heavy radial and axial loads, making them suitable for applications involving significant load-bearing requirements.

Temperature Resistance: These bearings can operate efficiently in a wide range of temperatures, from sub-zero conditions to high-temperature environments, without compromising performance.

Speed Capability: Tapered Roller Bearings - TS (Tapered Single) are capable of accommodating high rotational speeds, ensuring smooth operation and minimal frictional losses.

Load Distribution: The tapered design of the rollers and raceways allows for uniform load distribution, reducing stress concentrations and extending the service life of the bearings.

Case Studies

Numerous case studies demonstrate the tangible benefits of employing Tapered Roller Bearings - TS (Tapered Single) in various industrial applications. These case studies highlight significant improvements in equipment efficiency, reduced downtime, and enhanced reliability achieved through the use of TS bearings. Whether in automotive, aerospace, or industrial settings, the implementation of TS bearings has resulted in cost savings, improved performance, and increased competitiveness for businesses across different sectors.

Conclusion

Tapered Roller Bearings - TS (Tapered Single) play a vital role in unlocking efficiency and enhancing the performance of machinery and equipment across diverse industries. Their versatility, durability, and performance characteristics make them indispensable components in automotive, aerospace, and industrial applications. By understanding the applications and performance characteristics of TS bearings, industries can optimize their equipment design and operation, leading to increased efficiency, reduced friction, and enhanced reliability.

|

Brand |

Description |

|

SKF |

SKF 6206RS Bearings are known for their high-quality construction, precision engineering, and durability. They are designed to withstand heavy loads and provide reliable performance in various industrial applications. SKF bearings are widely recognized for their superior quality and long service life. |

|

FAG |

FAG 6206RS Bearings are renowned for their exceptional reliability and performance. With a focus on precision manufacturing and innovative design, FAG bearings offer excellent load-bearing capacity and resistance to wear and tear. They are trusted by industries worldwide for their consistent performance and durability. |

|

NSK |

NSK 6206RS Bearings are characterized by their advanced technology and superior engineering. These bearings are manufactured to the highest standards, ensuring smooth operation and reduced friction. NSK bearings are widely used in automotive, industrial, and aerospace applications, known for their reliability and longevity. |

|

NTN |

NTN 6206RS Bearings are known for their high-quality materials and precision engineering. With a focus on performance and reliability, NTN bearings deliver exceptional load-carrying capacity and long service life. They are suitable for a wide range of applications, including automotive, agricultural, and industrial machinery. |

|

Timken |

Timken 6206RS Bearings are designed for heavy-duty applications, offering unmatched durability and performance. These bearings feature advanced technology and innovative design, providing superior load capacity and resistance to wear. Timken bearings are trusted by industries worldwide for their reliability and longevity. |

Installation and Maintenance Best Practices for Tapered Roller Bearings - TS (Tapered Single)

Proper installation and maintenance are essential for ensuring the optimal performance and longevity of Tapered Roller Bearings - TS (Tapered Single). Below are guidelines and recommendations for achieving this:

Shaft and Housing Considerations:

Shaft and Housing Dimensions: Before installation, carefully measure and assess the dimensions of the shaft and housing to ensure compatibility with the TS bearings. Proper fit and alignment are crucial for preventing misalignment issues and premature wear.

Surface Finish: Ensure that the surfaces of the shaft and housing are smooth and free from burrs or defects that could cause damage to the bearings.

Preload Adjustment:

Follow Manufacturer Guidelines: Adjust the preload of the bearings according to the manufacturer's specifications and recommendations. Proper preload adjustment ensures optimal load distribution within the bearings and prevents excessive stress or strain.

Alignment Techniques:

Utilize Alignment Tools: Employ appropriate alignment techniques, such as laser alignment or dial indicators, to ensure that the Tapered Roller Bearings - TS are correctly aligned with the shaft and housing. Proper alignment minimizes the risk of premature wear and extends bearing life.

Maintenance Recommendations:

Regular Inspection:

Implement Scheduled Inspections: Establish regular maintenance schedules to inspect the condition of the Tapered Roller Bearings - TS. Periodic inspections should include checking for abnormal noise, vibration, and signs of wear or damage.

Detect Early Signs of Wear: Monitor bearing condition closely and be vigilant for early indicators of wear or damage, such as discoloration, pitting, or irregularities on bearing surfaces.

Condition Monitoring:

Utilize Monitoring Techniques: Implement condition monitoring techniques, such as vibration analysis and temperature monitoring, to assess the health of the bearings. Early detection of abnormalities allows for timely intervention and prevents catastrophic failures.

Investigate Root Causes: Investigate and address the root causes of any observed issues to prevent recurrence and ensure long-term reliability.

Lubrication Practices:

Select Suitable Lubricants: Choose lubricants that are compatible with the operating conditions and environment of the application. Consider factors such as temperature, speed, and load when selecting lubricants for Tapered Roller Bearings - TS.

Optimize Lubrication Methods: Implement effective lubrication methods, such as oil bath, grease replenishment, or automatic lubrication systems, to ensure adequate lubrication of the bearings. Proper lubrication minimizes friction, reduces wear, and extends bearing service life.

Conclusion:

In conclusion, adherence to proper installation and maintenance best practices is essential for maximizing the efficiency, performance, and longevity of Tapered Roller Bearings - TS (Tapered Single). By following these guidelines and recommendations, engineers and maintenance professionals can ensure the reliable operation of equipment and machinery in various industrial applications. Regular inspections, condition monitoring, and appropriate lubrication practices are key pillars in achieving optimal bearing performance and reliability.

Recent Advancements in Tapered Roller Bearings - TS (Tapered Single) Technology

In recent years, significant advancements have been made in the field of Tapered Roller Bearings TS (Tapered Single), aimed at enhancing efficiency, reliability, and performance. Let's delve into the latest innovations shaping the landscape of TS bearings:

|

Aspect |

Description |

|

Improved Materials |

Manufacturers have developed new alloy compositions with enhanced mechanical properties, such as higher strength and improved wear resistance. |

|

|

Enhanced surface treatments, including nitriding, carburizing, and induction hardening, improve surface hardness and wear resistance in harsh conditions. |

|

Coatings and Surface Engineering |

Nano-coatings, such as diamond-like carbon (DLC) and ceramic coatings, reduce friction and enhance wear resistance on TS bearings. |

|

|

Surface texturing techniques, like laser patterning and etching, create micro-roughness patterns to enhance oil retention and reduce friction losses. |

|

Sealing Solutions |

Advanced seal designs, such as labyrinth seals and lip seals, improve ingress protection and contamination resistance in TS bearings. |

|

|

Integrated sensor technology, including RFID tags and wireless sensors, allows real-time monitoring of bearing condition, enabling proactive maintenance. |

Future Developments and Implications:

Smart Bearings: The future of Tapered Roller Bearings - TS lies in the evolution of smart bearing technologies, where bearings will be equipped with embedded sensors and IoT connectivity for real-time monitoring and data analytics. This predictive maintenance approach will revolutionize equipment reliability and uptime, minimizing downtime and optimizing asset performance.

Advanced Manufacturing Techniques: Ongoing advancements in additive manufacturing (3D printing) and precision machining will enable the production of complex, customized TS bearings with optimized geometries and performance characteristics. This will open up new possibilities for tailored bearing solutions across diverse industries, further driving efficiency and innovation.

In summary, the continuous evolution of Tapered Roller Bearings - TS technology is ushering in a new era of efficiency, reliability, and performance in mechanical systems. From advanced materials and coatings to smart bearing solutions, these innovations are poised to transform the way TS bearings are designed, manufactured, and utilized, unlocking new levels of efficiency and productivity across various industries.

Recap of Tapered Roller Bearings - TS (Tapered Single)

In conclusion, the mechanics of Tapered Roller Bearings - TS (Tapered Single) play a pivotal role in various mechanical systems, offering unparalleled efficiency and reliability. we have delved into the intricate design and functionality of TS bearings, highlighting their unique tapered shape and robust construction.

Advantages and Applications

Tapered Roller Bearings - TS (Tapered Single) offer numerous advantages over traditional bearing designs, including the ability to handle both radial and axial loads simultaneously. Their versatility makes them indispensable in a wide range of applications, from automotive and aerospace to industrial machinery and equipment.

Critical Role in Efficiency

The critical role of Tapered Roller Bearings - TS (Tapered Single) in unlocking efficiency cannot be overstated. These bearings are engineered to minimize friction, reduce energy consumption, and optimize equipment performance. By incorporating TS bearings into mechanical systems, engineers can achieve significant gains in efficiency and productivity.

Call to Action

As we conclude, it is imperative for industry professionals to recognize the importance of Tapered Roller Bearings - TS (Tapered Single) and harness their potential to drive innovation and advancement in various sectors. By embracing TS bearing technology, organizations can elevate equipment reliability, reduce maintenance costs, and enhance overall operational efficiency.

In essence, Tapered Roller Bearings - TS (Tapered Single) represent a cornerstone of modern engineering, embodying the principles of efficiency, reliability, and performance excellence. It is our collective responsibility to leverage this technology to propel industries forward into a future of unparalleled success and prosperity.

Common Questions About Tapered Roller Bearings - TS (Tapered Single)

As experts in the field of bearings, it's common for individuals to have questions regarding Tapered Roller Bearings - TS (Tapered Single). Here, we address some of the frequently asked questions to provide clarity and insights into the mechanics and applications of TS bearings.

What are Tapered Roller Bearings - TS (Tapered Single)?

Tapered Roller Bearings - TS (Tapered Single) are a type of rolling-element bearing designed to accommodate both radial and axial loads. They feature tapered rollers and inner and outer rings with tapered raceways, allowing for efficient load distribution.

How do Tapered Roller Bearings - TS (Tapered Single) work?

TS bearings work by transmitting forces from the inner ring to the tapered rollers and then to the outer ring. The tapered design enables the rollers to handle both radial and axial loads, making them suitable for applications requiring high load-carrying capacity and rigidity.

What are the advantages of Tapered Roller Bearings - TS (Tapered Single)?

One of the key advantages of TS bearings is their ability to handle combined radial and axial loads. They also offer high stiffness, durability, and resistance to misalignment. Additionally, TS bearings are relatively easy to install and maintain.

Where are Tapered Roller Bearings - TS (Tapered Single) commonly used?

TS bearings find widespread applications in various industries, including automotive, aerospace, construction, and industrial machinery. They are commonly used in gearboxes, wheel hubs, axles, and transmission systems due to their ability to withstand heavy loads and high speeds.

How do I select the right Tapered Roller Bearings - TS (Tapered Single) for my application?

When selecting TS bearings, factors such as load capacity, speed, operating temperature, and environmental conditions should be considered. It's essential to consult with bearing manufacturers or engineers to ensure the proper selection and installation of TS bearings for specific applications.

What maintenance is required for Tapered Roller Bearings - TS (Tapered Single)?

Regular maintenance, including lubrication and periodic inspections, is crucial for ensuring the optimal performance and longevity of TS bearings. Lubricants should be applied according to manufacturer recommendations, and bearings should be inspected for signs of wear or damage regularly.

How can I extend the service life of Tapered Roller Bearings - TS (Tapered Single)?

Proper installation, lubrication, and maintenance are essential for extending the service life of TS bearings. Additionally, avoiding excessive loads, shock loads, and misalignment can help prolong bearing life and prevent premature failure.

These FAQs aim to provide a comprehensive understanding of Tapered Roller Bearings - TS (Tapered Single) and address common queries encountered by professionals in the field of bearings.