6206 rs Bearing Unleashed: EuroCrafted Precision at its Finest

Introduction

Precision bearings play a crucial role in various industries, particularly in EuroCrafted sectors where excellence in engineering is paramount. Among these precision bearings, the 6206RS bearings stand out for their exceptional performance and reliability.

Significance of Precision Bearings in EuroCrafted Industries

In EuroCrafted industries, where meticulous attention to detail and superior quality are fundamental, precision bearings serve as the backbone of machinery and equipment. These bearings are engineered to withstand demanding operating conditions while maintaining precise motion control and ensuring optimal performance.

Overview of 6206RS Bearings

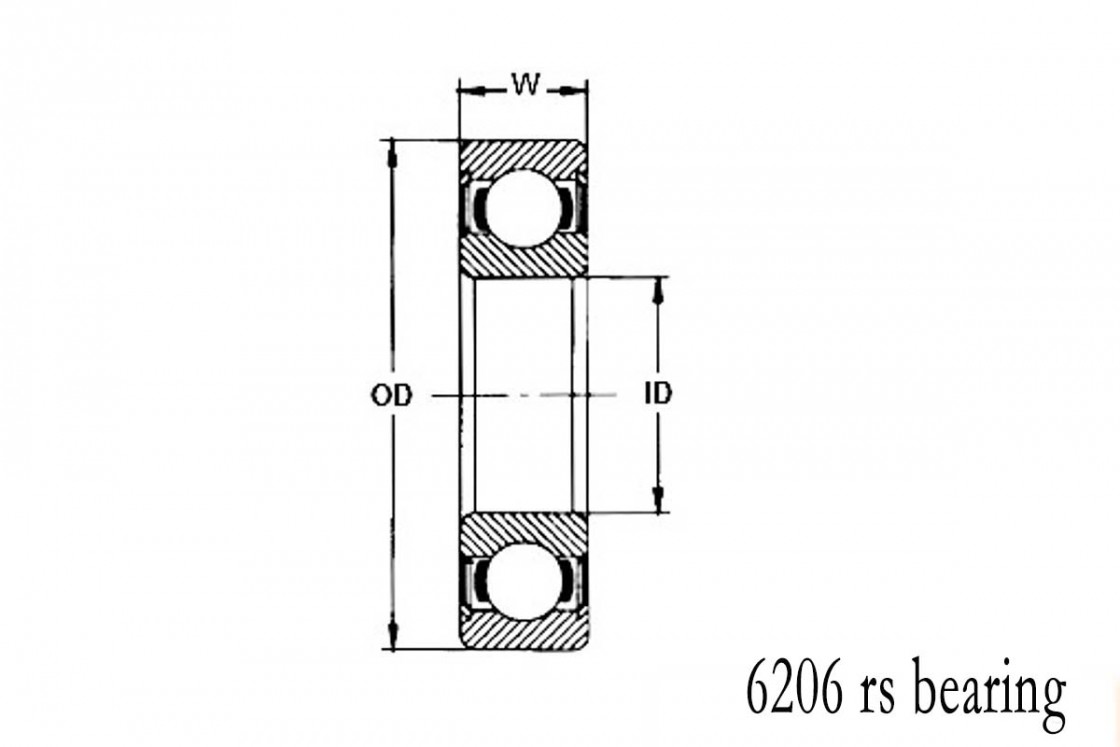

6206RS bearings are a type of sealed ball bearings designed to accommodate radial and axial loads in various applications. With dimensions of 30x62x16, these bearings offer a perfect balance of size and performance, making them suitable for a wide range of EuroCrafted machinery and equipment.

Key Features of 6206RS Bearings

Sealed Design: The sealed design of 6206RS bearings provides protection against contamination, moisture, and debris, ensuring extended bearing life and reliability.

Optimized Geometry: These bearings are engineered with optimized geometries to minimize friction and reduce heat generation, enhancing overall efficiency.

Precision Manufacturing: EuroCrafted precision engineering ensures the highest level of accuracy and consistency in the production of 6206RS bearings, guaranteeing superior performance and durability.

Role in Delivering Superior Performance

6206RS bearings play a pivotal role in delivering superior performance in EuroCrafted machinery and equipment. Their precise construction and high-quality materials enable smooth and efficient operation, contributing to increased productivity and reduced downtime.

Unveiling the Features of 6206 RS Bearings

we will delve into the features of 6206 RS bearings, uncovering the intricacies of their design and components that make them stand out in terms of precision and durability.

Structure and Components of 6206 RS Bearings

6206 RS bearings are meticulously engineered to meet the rigorous demands of various applications, particularly in EuroCrafted industries where precision and reliability are paramount. Let's explore the key components and structure of these sealed ball bearings:

|

Outer Ring |

The outer ring of 6206 RS bearings is designed to provide structural support and rigidity. It is precisely machined to ensure smooth rotation and proper alignment within the bearing assembly. |

|

Inner Ring |

Complementing the outer ring, the inner ring of 6206 RS bearings houses the rolling elements and retains them in position. It is manufactured with high-grade materials to withstand radial and axial loads while maintaining dimensional stability. |

|

Rolling Elements |

6206 RS bearings feature high-quality rolling elements, typically ball bearings, arranged in a circular pattern between the inner and outer rings. These rolling elements facilitate smooth motion transmission and distribute loads evenly across the bearing surfaces. |

|

Cage or Retainer |

A cage or retainer holds the rolling elements in place, preventing them from coming into contact with each other and ensuring proper spacing. This component also aids in reducing friction and minimizing wear, thus extending the service life of the bearings. |

|

Seal |

One of the defining features of 6206 RS bearings is their sealed design. The seal acts as a barrier, preventing contaminants such as dirt, dust, and moisture from infiltrating the bearing internals. This enhances reliability and prolongs the operating life of the bearings, especially in challenging environments.

|

Key Features Contributing to Precision and Durability

6206 RS bearings boast several features that set them apart in terms of precision engineering and long-lasting performance. Let's highlight some of these key features:

High-Quality Materials: EuroCrafted precision ensures that 6206 RS bearings are crafted from top-grade materials, such as stainless steel or chrome steel, known for their exceptional strength and corrosion resistance.

Tight Tolerances: The manufacturing process involves stringent quality control measures to maintain tight tolerances, resulting in precise dimensions and consistent performance of the bearings.

Advanced Sealing Technology: The seals used in 6206 RS bearings are engineered with advanced technology to provide superior protection against contamination, extending the bearing's service life and reducing maintenance requirements.

Enhanced Lubrication: Proper lubrication is essential for the smooth operation of bearings. 6206 RS bearings are designed to retain lubricants effectively, ensuring optimal lubrication distribution and minimizing frictional losses.

Robust Construction: EuroCrafted precision engineering techniques result in robust construction, capable of withstanding heavy loads, high speeds, and harsh operating conditions without compromising performance.

By understanding and appreciating the features of 6206 RS bearings, industries can leverage their EuroCrafted precision to achieve optimal performance and reliability in their machinery and equipment.

Applications Across EuroCrafted Industries

we will delve into the wide array of EuroCrafted industries that benefit from the utilization of 6206 RS bearings. Through case studies and real-world examples, we will highlight how these precision bearings elevate the performance and reliability of machinery and equipment across various sectors.

Diverse Industries Utilizing 6206 RS Bearings

6206 RS bearings find applications across a multitude of EuroCrafted industries, thanks to their unparalleled precision and durability. Let's explore some of these industries:

Automotive Sector

In the automotive industry, where precision and reliability are paramount, 6206 RS bearings play a crucial role in various components such as wheel hubs, transmissions, and engines. The EuroCrafted precision ensures smooth operation and long-lasting performance, contributing to the overall efficiency and safety of vehicles.

Aerospace and Aviation

In the aerospace and aviation sectors, where extreme conditions and rigorous demands are commonplace, 6206 RS bearings provide essential support in critical applications like aircraft engines, landing gear systems, and control mechanisms. Their sealed design and precise engineering withstands high speeds, vibrations, and temperature fluctuations, ensuring optimal performance in the skies.

Manufacturing and Machinery

EuroCrafted precision bearings are indispensable in manufacturing and machinery industries, where precision and efficiency are paramount. 6206 RS bearings find applications in various equipment such as CNC machines, robotics, conveyor systems, and industrial gearboxes, where they contribute to smooth motion, reduced downtime, and enhanced productivity.

Renewable Energy

In the renewable energy sector, particularly in wind turbines and solar panel tracking systems, 6206 RS bearings play a vital role in harnessing clean energy efficiently. Their sealed design protects against environmental contaminants, while their precision engineering ensures reliable operation, contributing to the sustainability and reliability of renewable energy sources.

Case Studies Demonstrating Performance Enhancement

Let's explore some case studies highlighting how 6206 RS bearings have revolutionized performance in EuroCrafted machinery and equipment:

Automotive Manufacturing Plant

In an automotive manufacturing plant, the adoption of 6206 RS bearings in assembly line robots resulted in a significant reduction in maintenance downtime. The precision engineering of these bearings minimized wear and tear, leading to smoother operation and increased production output.

Aerospace Component Supplier

A supplier of aerospace components integrated 6206 RS bearings into their aircraft landing gear systems. The sealed design of these bearings ensured reliable performance even under harsh conditions, reducing the risk of failures and enhancing the safety of aircraft operations.

Renewable Energy Project

In a large-scale renewable energy project, the utilization of 6206 RS bearings in wind turbine gearboxes contributed to improved energy efficiency and extended service life. The precision engineering of these bearings minimized friction losses, optimizing power generation and reducing maintenance costs.

Conclusion

In conclusion, 6206 RS bearings are indispensable components across a wide range of EuroCrafted industries, delivering unmatched precision, reliability, and performance. Through case studies and real-world examples, we have witnessed how these bearings elevate the efficiency and functionality of machinery and equipment, reinforcing their status as EuroCrafted precision at its finest.

|

Brand |

Features |

Advantages |

Disadvantages |

|

SKF |

High-quality steel construction, superior sealing |

Enhanced durability, resistance to contamination |

Higher initial cost, limited availability |

|

FAG |

Robust design, advanced sealing technology |

Excellent performance in high-speed applications |

Slightly higher friction, premium pricing |

|

NTN |

Precision engineering, innovative lubrication system |

Consistent performance, reduced maintenance needs |

Limited product range, higher upfront cost |

|

NSK |

Corrosion-resistant coatings, extensive product line |

Extended lifespan, suitability for harsh environments |

Higher pricing, limited availability |

|

Timken |

High load capacity, precision manufacturing |

Exceptional durability, reliable performance |

Higher cost compared to some competitors |

Maintenance and Care Guidelines

we will outline comprehensive guidelines for the proper maintenance and care of 6206 RS bearings. Regular maintenance is crucial for ensuring the longevity and optimal performance of these precision bearings. We will emphasize the importance of regular inspections and lubrication routines in preserving the EuroCrafted precision at its finest.

Importance of Maintenance

6206RS bearings are precision-engineered components that operate under demanding conditions. Proper maintenance is essential to ensure their reliability, longevity, and optimal performance. Neglecting maintenance can lead to premature wear, reduced efficiency, and even failure of the bearings, resulting in costly downtime and repairs.

Inspection Procedures

Regular inspections are the cornerstone of 6206RS bearings maintenance. Here are the key inspection procedures to follow:

Visual Inspection

Inspect the bearings visually for any signs of damage, wear, or contamination. Look for cracks, dents, discoloration, or any irregularities on the bearing surfaces.

Clearance Measurement

Measure the internal clearance of the bearings using appropriate tools. Excessive clearance or tightness can indicate potential issues that require attention.

Noise and Vibration Analysis

Monitor the bearings during operation for any abnormal noise or vibration, which could indicate misalignment, imbalance, or bearing damage.

Lubrication Practices

Proper lubrication is critical for 6206RS bearings to reduce friction, dissipate heat, and prevent premature wear. Follow these lubrication practices:

Selection of Lubricant

Choose a high-quality lubricant suitable for the operating conditions and temperature range of the bearings. Ensure compatibility with the sealing material to maintain the integrity of the seals.

Lubrication Interval

Establish a regular lubrication interval based on the operating conditions and manufacturer recommendations. Over-lubrication or under-lubrication can lead to bearing damage.

Lubrication Method

Apply the lubricant evenly and in the correct quantity using appropriate lubrication tools or systems. Ensure proper distribution to all bearing surfaces to prevent dry running or excess lubricant buildup.

Environmental Considerations

Protect 6206RS bearings from environmental factors such as moisture, dust, and contaminants, which can accelerate wear and corrosion. Utilize appropriate sealing arrangements and housing designs to minimize exposure to harmful elements.

Conclusion

In conclusion, proper maintenance and care are essential for preserving the EuroCrafted precision of 6206RS bearings. By following comprehensive guidelines for inspection, lubrication, and environmental protection, you can ensure the longevity and optimal performance of these precision components, maintaining EuroCrafted precision at its finest.

Introduction to EuroCrafted Precision with 6206 RS Bearings

EuroCrafted precision engineering has long been associated with excellence in design and manufacturing. When it comes to components like bearings, the emphasis on quality and performance is paramount. In this article, we delve into the advantages of using 6206 RS bearings in EuroCrafted applications, exploring how they embody precision and reliability to meet the demanding standards of EuroCrafted industries.6206 RS bearings, with their robust construction and meticulous design, epitomize the essence of EuroCrafted precision.

Advantages of EuroCrafted Precision

EuroCrafted precision engineering sets a high standard for quality and performance, and 6206 RS bearings meet and exceed these expectations. Here are the key advantages of integrating these bearings into EuroCrafted applications:

Reliability: EuroCrafted industries demand components that can withstand rigorous operating conditions and deliver consistent performance over time. 6206 RS bearings are engineered to provide reliable operation, ensuring smooth functioning even in the most demanding EuroCrafted environments.

Efficiency: Efficiency is at the core of EuroCrafted precision, and 6206 RS bearings contribute significantly to optimizing system performance. Their low-friction design minimizes energy loss, enhancing overall efficiency in EuroCrafted machinery and equipment.

Longevity: EuroCrafted precision emphasizes longevity and durability, and 6206 RS bearings are built to last. With superior materials and advanced manufacturing techniques, these bearings offer extended service life, reducing the need for frequent replacements and maintenance in EuroCrafted applications.

In conclusion, 6206 RS bearings represent the epitome of EuroCrafted precision at its finest. Their reliability, efficiency, and longevity make them indispensable components in a wide range of EuroCrafted machinery and equipment, ensuring superior performance and durability in every application.

Future Trends and Innovations in EuroCrafted Precision Bearings

In the realm of EuroCrafted precision engineering, innovation is a driving force that propels industries forward. As we look to the future, the evolution of 6206 RS bearings is poised to undergo significant advancements, reshaping the landscape of EuroCrafted machinery and equipment. Let's delve into the emerging trends and potential innovations that are set to revolutionize EuroCrafted precision bearing technology.

|

Emerging Trends |

|

|

Advanced Materials |

One of the key trends shaping the future of 6206 RS bearings is the development of advanced materials with enhanced properties. Manufacturers are exploring new alloys and composites that offer superior strength, durability, and resistance to wear and corrosion. These advancements will result in bearings that can withstand even the harshest EuroCrafted operating environments. |

|

Smart Bearing Technology |

The integration of smart technologies into 6206 RS bearings is another notable trend on the horizon. Sensors embedded within the bearings will enable real-time monitoring of performance metrics such as temperature, vibration, and load. This data can be used to optimize maintenance schedules, predict potential failures, and enhance overall efficiency in EuroCrafted applications. |

|

Potential Innovations |

|

|

Nano-coating Technology |

Nano-coatings hold immense potential for revolutionizing the performance of 6206 RS bearings. These ultra-thin coatings can reduce friction, minimize wear, and improve resistance to contaminants, resulting in bearings that operate more efficiently and have a longer service life. In EuroCrafted industries where precision is paramount, nano-coatings could offer significant advantages. |

|

3D Printing |

Additive manufacturing, or 3D printing, is poised to disrupt traditional bearing manufacturing processes. This technology allows for the production of complex geometries and customized designs, opening up new possibilities for optimizing the performance of 6206 RS bearings in EuroCrafted applications. From lightweight components to intricate internal structures, 3D printing has the potential to drive innovation in EuroCrafted precision bearing technology. |

In conclusion, the future of 6206 RS bearings in EuroCrafted precision engineering is characterized by a convergence of advanced materials, smart technologies, and innovative manufacturing processes. By staying at the forefront of emerging trends and embracing potential innovations, EuroCrafted industries can continue to elevate the standard of precision and performance in their machinery and equipment.

Conclusion: Unlocking EuroCrafted Precision with 6206 RS Bearings

In conclusion, the exploration of 6206 RS bearings reveals a crucial aspect of EuroCrafted precision engineering. These bearings, with their remarkable specifications of 30x62x16 and sealed design, epitomize excellence in the field of precision machinery. Throughout this discussion, several key insights and benefits have emerged, showcasing the indispensable role of 6206 RS bearings in EuroCrafted applications.

Superior Performance: The 6206 RS bearings exhibit unparalleled performance characteristics, thanks to their precise design and construction. With a sealed ball bearing configuration, they offer enhanced protection against contaminants and moisture ingress, ensuring reliable operation even in demanding EuroCrafted environments.

EuroCrafted Precision: EuroCrafted industries demand the highest levels of precision and quality in their machinery and equipment. The precision-engineered design of 6206 RS bearings meets these exacting standards, contributing to the smooth operation and efficiency of EuroCrafted machinery across various sectors.

Reliability and Longevity: One of the standout features of 6206 RS bearings is their exceptional reliability and longevity. Built to withstand the rigors of EuroCrafted applications, these bearings deliver consistent performance over extended periods, minimizing downtime and maintenance costs for EuroCrafted operators.

Enhanced Efficiency: By reducing friction and minimizing wear, 6206 RS bearings contribute to improved efficiency and energy savings in EuroCrafted machinery. Their optimized design and sealed construction ensure minimal power loss, allowing EuroCrafted industries to maximize productivity and profitability.

In summary, 6206 RS bearings represent the epitome of EuroCrafted precision at its finest. With their unmatched performance, reliability, and efficiency, these bearings play a pivotal role in driving innovation and excellence across EuroCrafted industries. As EuroCrafted precision engineering continues to evolve, 6206 RS bearings will remain a cornerstone of success, empowering EuroCrafted operators to achieve new heights of performance and reliability in their machinery and equipment.

FAQs: Common Questions About 6206RS 30x62x16 Sealed Ball Bearings

we'll address some frequently asked questions regarding 6206RS 30x62x16 sealed ball bearings, shedding light on their features, applications, and advantages in EuroCrafted precision engineering.

Q1: What are the key specifications of 6206RS bearings?

A1: 6206RS bearings are characterized by their dimensions of 30x62x16, denoting a bore diameter of 30 mm, an outer diameter of 62 mm, and a width of 16 mm. The "RS" designation signifies that they are sealed ball bearings, offering enhanced protection against contaminants and debris ingress.

Q2: What industries commonly utilize 6206RS bearings?

A2: 6206RS bearings find extensive applications across various EuroCrafted industries, including automotive manufacturing, aerospace engineering, precision machinery, and industrial automation. Their versatility and reliability make them indispensable components in EuroCrafted precision engineering.

Q3: What are the advantages of using 6206RS bearings in EuroCrafted applications?

A3: The advantages of 6206RS bearings in EuroCrafted precision engineering are manifold. Firstly, their sealed design ensures superior protection against environmental factors, prolonging bearing life and minimizing maintenance requirements. Additionally, their precision-engineered construction facilitates smooth and efficient operation, contributing to the overall performance and reliability of EuroCrafted machinery and equipment.

Q4: How do 6206RS bearings contribute to EuroCrafted precision engineering?

A4: 6206RS bearings play a crucial role in EuroCrafted precision engineering by providing the necessary stability, accuracy, and durability required in demanding applications. Their precise dimensions and sealed design make them ideal for use in high-precision EuroCrafted machinery, where consistent performance and reliability are paramount.

Q5: What maintenance practices are recommended for 6206RS bearings?

A5: To ensure optimal performance and longevity, regular maintenance practices are essential for 6206RS bearings. This includes periodic inspections to check for signs of wear or damage, as well as lubrication routines to keep the bearings operating smoothly. By adhering to recommended maintenance procedures, EuroCrafted operators can maximize the lifespan and efficiency of their machinery and equipment.

Q6: Where can EuroCrafted operators procure high-quality 6206RS bearings?

A6: High-quality 6206RS bearings are available from reputable manufacturers and distributors specializing in EuroCrafted precision engineering components. Brands such as SKF, FAG, and NSK are renowned for their commitment to quality and innovation, offering a wide range of bearings tailored to EuroCrafted applications.

In summary, 6206RS 30x62x16 sealed ball bearings represent a cornerstone of EuroCrafted precision engineering, delivering unmatched performance, reliability, and durability across diverse applications. By addressing these common questions, we hope to provide clarity and insight into the significance of 6206RS bearings in EuroCrafted industries.