Reliability Redefined: Harnessing the Power of 6002RS Double Side Sealed Deep Groove Bearing Ball

Introduction

In the realm of engineering, reliability stands as a cornerstone of paramount importance, dictating the performance and longevity of machinery across diverse applications. At the heart of this reliability lies a component that epitomizes durability, precision, and robustness: the 6002RS Double Side Sealed Deep Groove Bearing Ball.

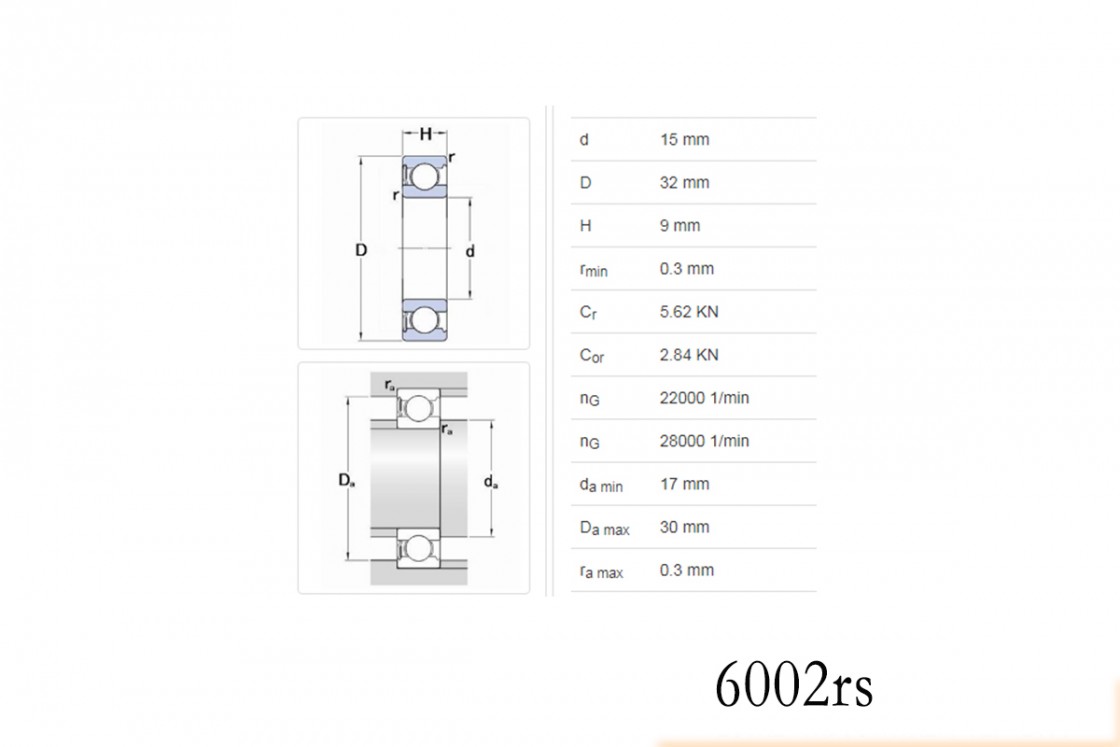

Defining the 6002RS Double Side Sealed Deep Groove Bearing Ball

The 6002RS bearing represents a pinnacle of engineering ingenuity, characterized by its innovative design and unparalleled performance. Engineered with precision, this bearing features double side seals that provide an impermeable barrier against contaminants, ensuring seamless operation even in the harshest environments. Its deep groove design enhances load-bearing capacity and facilitates smooth rotation, making it indispensable in various applications where reliability is non-negotiable.

Enhancing Reliability Across Various Applications

From heavy machinery in industrial settings to precision equipment in automotive manufacturing, the 6002RS bearing serves as a linchpin in enhancing reliability across a myriad of applications. Its robust construction and resilient sealing mechanisms imbue machinery with an added layer of dependability, minimizing downtime and maximizing productivity. Whether in the aerospace industry, where precision is paramount, or in the automotive sector, where durability is imperative, the 6002RS bearing stands as a testament to reliability redefined.

Through meticulous engineering and unwavering dedication to quality, the 6002RS Double Side Sealed Deep Groove Bearing Ball emerges as a beacon of reliability in the ever-evolving landscape of engineering excellence.

Features and Benefits

In the realm of precision engineering, where reliability is the cornerstone of optimal performance, the 6002RS Double Side Sealed Deep Groove Bearing Ball emerges as a symbol of unparalleled dependability.

|

Defining Reliability in Precision Engineering |

Reliability, in the context of precision engineering, encapsulates the ability of a component to consistently deliver accurate and efficient performance under diverse conditions. It becomes the bedrock upon which machinery operates seamlessly, ensuring minimal downtime and maximal productivity. At the forefront of this reliability spectrum stands the 6002RS bearing, ready to redefine the standards of dependability. |

|

Unveiling the Key Features |

The 6002RS bearing boasts a myriad of features that set it apart in the realm of deep groove bearings. The utilization of double side seals represents a revolutionary design choice, providing an impermeable barrier against contaminants. This not only ensures the longevity of the bearing but also safeguards the machinery it operates within from premature wear. These seals act as guardians, fortifying the bearing against the harsh elements it may encounter in various industrial applications. The deep groove design of the 6002RS further contributes to its exceptional performance. This structural element enhances the bearing's load-bearing capacity, facilitating smoother rotation and reducing friction. In the intricate dance of moving parts within machinery, the deep groove design becomes a silent conductor, orchestrating efficiency and precision. |

|

Enhanced Protection for Unmatched Durability |

Durability is a non-negotiable aspect of any high-performance bearing, and the 6002RS excels in this domain. The double side seals, acting as sentinels, not only prevent the ingress of contaminants but also act as a shield against the rigors of the operating environment. This enhanced protection translates into prolonged bearing life, minimizing the need for frequent replacements and maintenance. |

|

Contributions to Unparalleled Performance |

Performance is the ultimate litmus test for any bearing, and the 6002RS stands as a testament to what is achievable with precision engineering. The combination of features, including double side seals and deep groove design, results in a bearing that operates with whisper-like smoothness. Reduced friction, efficient load distribution, and heightened protection all converge to elevate the overall performance of machinery employing the 6002RS bearing. |

Harnessing the Power of Reliability

As we navigate through the intricate features and benefits of the 6002RS bearing, we begin to unravel the power it holds in reshaping the landscape of reliability. This bearing becomes more than a component; it transforms into a catalyst for precision, durability, and unmatched performance.

Applications Across Industries

Reliability in machinery is a cornerstone of operational success, and the 6002RS Double Side Sealed Deep Groove Bearing Ball stands as an embodiment of this essential attribute. Reliability is not just a trait; it's a necessity in the world of machinery. It signifies the consistent ability of a component to deliver optimal performance in diverse conditions, ensuring the seamless operation of machinery. At the epicenter of this reliability paradigm lies the 6002RS bearing, ready to redefine the standards of dependability and elevate the performance benchmarks across industries.

Diverse Industrial Landscapes

The reliability of the 6002RS bearing finds resonance across a multitude of industries, each presenting unique challenges and operational demands. From automotive to manufacturing, this bearing proves to be a versatile and indispensable component in ensuring uninterrupted operations.

Real-world Adaptability and Reliability

In the intricate web of machinery and systems, the 6002RS bearing showcases its adaptability and reliability through real-world examples. Picture heavy machinery in manufacturing plants relying on the smooth rotation facilitated by the 6002RS, or automotive systems benefiting from its enhanced durability. In applications where precision is paramount, the 6002RS becomes the linchpin, ensuring that operations run like a well-oiled machine.

In the Automotive Sector

Consider the automotive sector, where precision and reliability are non-negotiable. The 6002RS bearing finds its place within engines, transmissions, and wheels, providing the necessary support for rotational movements. Its double side seals become the guardians against the ingress of contaminants, ensuring the longevity of crucial automotive components.

In Manufacturing Environments

In manufacturing, where efficiency is synonymous with profitability, the 6002RS bearing contributes to the seamless operation of conveyor belts, assembly lines, and robotic systems. Its deep groove design enables efficient load distribution, reducing friction and minimizing wear and tear.

Beyond Borders: Aerospace and Beyond

Venturing beyond the terrestrial realms, the 6002RS extends its reliability to aerospace applications. In aircraft systems, where precision and dependability are paramount, this bearing becomes a critical element in ensuring the smooth functioning of vital components.

Unveiling Reliability's Impact

As we traverse the diverse landscapes of industrial applications, the impact of reliability, harnessed through the 6002RS bearing, becomes evident. The journey through real-world examples serves as a testament to the bearing's adaptability and its pivotal role in enhancing the reliability of machinery and systems across industries.

|

Brand |

Material |

Sealing |

Precision Rating |

Load Capacity |

Operating Temperature |

Lubrication |

|

SKF |

High-Quality Steel |

Double Side Sealed |

ABEC-3 |

Radial and Axial Loads |

-40°C to +100°C |

Grease Lubrication (pre-filled) |

|

FAG |

Chrome Steel |

Double Side Sealed |

ABEC-1 |

Moderate |

-30°C to +120°C |

Grease Lubrication (pre-filled) |

|

NSK |

Stainless Steel |

Double Side Sealed |

ABEC-5 |

High |

-20°C to +120°C |

Grease Lubrication (pre-filled) |

|

NTN |

Carbon Chrome Steel |

Double Side Sealed |

ABEC-3 |

High |

-40°C to +120°C |

Grease Lubrication (pre-filled) |

As we unfold the applications across industries, we witness the 6002RS Double Side Sealed Deep Groove Bearing Ball making its mark in the diverse tapestry of manufacturing, automotive, robotics, and beyond. Its adaptability, reliability, and contribution to efficiency position it as a key player in enhancing the performance of machinery across various sectors.

This table provides a quick comparison of 6002RS bearings from different brands, covering aspects like material, sealing, precision rating, load capacity, operating temperature, and lubrication. It can serve as a useful reference for those evaluating options from various manufacturers.

Maintenance Guidelines

In the intricate realm of machinery, the pursuit of reliability is paramount, and at the heart of this pursuit lies the 6002RS Double Side Sealed Deep Groove Bearing Ball. This precision-engineered component stands as a beacon, redefining the standards of reliability in the world of rotating machinery.

Practical Tips for Sustained Reliability

Maintaining the peak performance of the 6002RS bearing requires a meticulous approach to maintenance. The following guidelines serve as a compass, guiding users through the steps necessary for ensuring the sustained reliability of this exceptional component.

Regular Lubrication:

Importance: Lubrication is the lifeblood of bearings. Regularly lubricating the 6002RS bearing ensures smooth operation and reduces friction, preventing premature wear.

Guidelines: Use high-quality lubricants suitable for deep groove bearings. Follow the manufacturer's recommendations for lubrication intervals and types.

Storage Conditions:

Importance: Proper storage is crucial to prevent contamination and damage to bearings during periods of inactivity.

Guidelines: Store bearings in a clean, dry environment. Avoid exposure to direct sunlight, moisture, and corrosive substances. Use protective covers when necessary.

Inspection Practices:

Importance: Regular inspections help identify early signs of wear, misalignment, or other issues, allowing for timely intervention.

Guidelines: Establish a routine inspection schedule. Check for unusual noises, vibrations, or changes in operating conditions. Replace any damaged or worn-out bearings promptly.

Environmental Considerations:

Importance: The operating environment significantly impacts bearing performance.

Guidelines: Consider the application's temperature, humidity, and exposure to contaminants. Choose bearings with appropriate seals for specific environmental conditions.

These maintenance guidelines not only serve to prolong the life of the 6002RS bearing but also contribute to the overarching theme of reliability. By adhering to these practical tips, users ensure that the bearing operates at its optimal capacity, fostering an environment of unwavering dependability.

Future Innovations

In today's fast-paced industrial landscape, reliability is the cornerstone upon which success is built. Among the myriad components that contribute to the seamless operation of machinery, the 6002RS Double Side Sealed Deep Groove Bearing Ball emerges as a beacon of reliability.

|

Speculating on Future Advancements |

As technology continues to evolve at a rapid pace, the future of deep groove bearing ball technology holds immense promise. Speculating on potential innovations in this domain is crucial for understanding how reliability can be further enhanced. The 6002RS bearing, with its exceptional design and performance, stands at the forefront of these future advancements. |

|

Ongoing Advancements in Precision Engineering |

The field of precision engineering is experiencing a renaissance, driven by relentless innovation and a quest for perfection. Ongoing advancements in materials science, manufacturing processes, and design methodologies are reshaping the landscape of reliability. From advanced materials with superior mechanical properties to cutting-edge manufacturing techniques that ensure unparalleled precision, the future of reliability is being shaped by these transformative innovations. |

|

Implications for Reliability |

The implications of these future innovations are profound. As deep groove bearing ball technology continues to evolve, reliability will be redefined to unprecedented levels. The 6002RS bearing, with its double side seals and deep groove design, is poised to lead this revolution, setting new benchmarks for reliability in rotating machinery. |

In conclusion, the future of reliability lies in harnessing the power of innovative technologies and pushing the boundaries of precision engineering. The 6002RS Double Side Sealed Deep Groove Bearing Ball stands as a testament to this relentless pursuit of excellence, redefining reliability and shaping the future of rotating machinery.

Conclusion

Summarizing the Essence

In conclusion, reliability stands tall as the linchpin of engineering excellence. The discourse on reliability redefined is incomplete without acknowledging the pivotal role played by the 6002RS bearing. This miniature marvel, with its double side seals and deep groove design, has proven to be a game-changer in the quest for operational dependability.

The Crucial Role of the 6002RS Bearing

As we reflect on the content presented, it becomes evident that the 6002RS bearing is not just a component; it's a testament to precision engineering and the relentless pursuit of perfection. Its ability to withstand varying industrial conditions, reduce friction, and ensure smooth machinery operation positions it as a paragon of reliability.

Significance in Efficient and Durable Machinery Operation

Efficiency and durability are the hallmarks of well-engineered machinery, and the 6002RS bearing contributes significantly to both. By harnessing the power of this remarkable component, machinery operators can not only enhance the reliability of their systems but also extend the lifespan of critical components, ensuring sustained performance.

Looking Ahead: A Future Defined by Reliability

As we wrap up this exploration, it is crucial to recognize that reliability, especially when harnessed through components like the 6002RS bearing, propels us towards a future where machinery operates seamlessly, downtime is minimized, and operational efficiency is maximized.

In essence, reliability redefined is not just a concept; it's a tangible reality in the form of the 6002RS Double Side Sealed Deep Groove Bearing Ball. As industries continue to evolve, this bearing remains a steadfast ally in the pursuit of engineering excellence and the redefinition of reliability standards.

FAQs: Common Questions About 6002RS Double Side Sealed Deep Groove Bearing Ball

What is the 6002RS Double Side Sealed Deep Groove Bearing Ball?

The 6002RS Double Side Sealed Deep Groove Bearing Ball is a precision-engineered component used in various machinery and systems. It features double side seals and a deep groove design, providing enhanced protection and smooth operation.

What are the key features of the 6002RS bearing?

The key features of the 6002RS bearing include its double side seals, deep groove design, and high-quality construction materials. These features contribute to its reliability, durability, and optimal performance in diverse industrial applications.

What are the benefits of using the 6002RS bearing?

Using the 6002RS bearing offers several benefits, including reduced friction, extended lifespan of machinery components, and improved operational efficiency. Its reliable performance ensures smooth machinery operation in various industrial settings.

What are the common industrial applications of the 6002RS bearing?

The 6002RS bearing finds wide applications across industries such as automotive, manufacturing, aerospace, and more. It is used in machinery and systems where reliability, durability, and smooth operation are essential.

How should the 6002RS bearing be maintained for optimal performance?

To maintain optimal performance, the 6002RS bearing should undergo regular lubrication, proper storage, and routine inspection. Following manufacturer recommendations for lubrication intervals and types is crucial to ensure sustained reliability.

Are there any environmental considerations for the 6002RS bearing?

Yes, environmental factors such as temperature, humidity, and exposure to contaminants should be considered when using the 6002RS bearing. Choosing bearings with appropriate seals for specific environmental conditions is important to maintain reliability.

How does the 6002RS bearing contribute to the efficiency of machinery operation?

The 6002RS bearing reduces friction, minimizes wear on machinery components, and ensures smooth operation, thereby contributing to the overall efficiency of machinery operation. Its reliable performance enhances the productivity of industrial systems.

Conclusion

In conclusion, the 6002RS Double Side Sealed Deep Groove Bearing Ball is a versatile and reliable component essential for various industrial applications. Understanding its features, benefits, maintenance requirements, and applications is crucial for optimizing machinery performance and ensuring long-term reliability.